SOSIAD (Association of Refrigeration Industry and Businessmen) organized its second thematic meeting supporting the fight against climate change and that is in the scope of UNIDO (United Nations Industrial Development Organization) Demonstration Project titled “Demonstration and Pilot Activities for Encouraging Low Global Warming Potential (GWP) Refrigerants in the Republic of Turkey” on Tuesday, November 26th at JW Marriott Hotel in Ankara. The meeting had a large turnout of students, academics, producers, final users, after-sale service providers, and representatives of non-governmental organizations.

SOSIAD Chairman of the Board of Directors Turgay Karakuş underlined that this Project realized with support of UNIDO and the Ministry of Environment and Urbanization is an awareness project. Noting that there are significant outcomes of the Project especially for investors, he continued to express transformation to alternative / natural refrigerants such as ammonia (NH3) and carbon dioxide (CO2) with lower GWP leads to serious economization on operating costs both for investors and industrialists. Karakuş also emphasized that they were thrilled with this Project covering all aspects of operation with significant impacts on the nature.

Ertürk: “HPMP (Hydrofluorocarbons Phase Out Management Plan) Project provides technical and technological support to transformation to alternative refrigerants and technologies”

Following Karakuş’s speech, Director of Ozone Layer Protection Unit Ülkü Füsun Ertürk from Climate Change and Adaptation Department of the Ministry of Environment and Urbanization gave information to participants about efforts undertaken by the Ministry towards protection of the Ozone Layer. Ertürk said: “the Vienna Convention for the Protection of Ozone Layer and its Montreal Protocol our country became part of in 1991 has been carried out under coordination of our Ministry. There are ongoing efforts to terminate importation and usage of Ozone-depleting substances in our country on a schedule. Committee of Foreign Affairs of Turkish Grand National Assembly accepted the Montreal Protocol and its Kigali Amendment targeting controlling and reducing floral greenhouse gases. Turkey has been contributing to joint efforts to fight against changes in the Ozone Layer and climate with other parties to the Montreal Protocol. The 20 million USD given by the financial mechanism of the Montreal Protocol until 2018 was used in our country in technology, technical support, and capacity development projects undertaken in cooperation with UN Industrial Development Organization (UNIDO) operators. Specifically the Demonstration Project with thematical meeting organized today is covered from HPMP Project budget which aims to terminate use of hydrofluorocarbon (HCFC) refrigerants. The HPMP Project demonstrated use of HCFC refrigerants in sectors such as foam, refrigeration, and air conditioning to provide technical and technological support to transition to alternative refrigerants and technologies. With HPMP Project a program of best practices for emission reduction is undertaken and train the trainer and service technicians trainings are given. A national evaluation program is established to develop application projects encouraging refrigerants with low GWP levels. The main purpose of Demonstration Project realized with cooperation of UNIDO and SOSIAD is to create awareness about using refrigerants with low GWP levels. Refrigerant or air-conditioning systems and units containing HCFC-22 in our country are transformed to natural refrigerant alternatives or with those that have low GWP levels. Target is to track or report on energy efficiency of new systems. In the coming period, applications to fight against climate change, protect the Ozone Layer, and gradually decrease floral greenhouse gases shall continue which are very important opportunities for direct transition to low GWP refrigerants.”

Orhan: “We are conducting changes in regulations in line with the change in refrigerants in global refrigeration sector”

Following Ertürk’s speech, Specialist at the Ministry of Environment and Urbanization, Onur Orhan made his presentation titled “General Evaluation of Regulation on Refrigerants in our Country”. In his presentation, Orhan informed participants about the Ministry regulation on refrigerants with low GWP values and said the following on development of gases: “Our journey that began with CFC’s is continuing with HCFC, HFC, PFC, and natural refrigerants. Our country has fulfilled its duties about such refrigerants in the framework of international regulations and released several regulations about these refrigerants over time. Efforts in line with these regulations are still going on.” Orhan noted there are efforts towards protection of the Ozone Layer and continued: “As a result of such efforts it was established that alternative refrigerants replacing the CFC’s cause global warming and later that other refrigerants also have some environmental impacts. Such other refrigerants included those with high or low global warming potentials. This is a technical development that influences our regulation. Thus, we are conducting changes in regulations in line with the change in refrigerants in global refrigeration sector. Among our efforts there are the Kigali Amendment and Regulation on Floral Greenhouse Gases.” Orhan mentioned that the Ministry has been conducting studies from the perspective of both the Kigali Amendment and Regulation on Floral Greenhouse Gases and added that there will be a quota system on imports and this system demonstrates significance of refrigerants with global warming potential. Orhan also made a global assessment and said: “The advantage of being in ‘A5 Group 1’ for Turkey is having a longer time to decrease and phase out of refrigerants with high GWP values.”

Aslantaş: “In the scope of the project, facilities in Izmir, Ankara, and Istanbul have successfully been transformed with alternative refrigerants”

Project Coordinator Kıvanç Aslantaş gave detailed information about the Demonstration Project and shed light on reasons behind and expected results from the project. Aslantaş said in the scope of the Project, facilities in Izmir, Ankara, and Istanbul have successfully been replaced with alternative refrigerants. He noted that transforming existing systems in these three cities to new generation refrigerants with lower GWP values is an encouraging force.

Aslantaş said: “Our first pilot Project we started with support of UNIDO and the Ministry of Environment and Urbanization was making industrial refrigeration application at Algida facilities with a carbon dioxide and cascade system. We compared this system applied in Izmir with the existing R717 / R744 (NH3/CO2) cascade system and R717 systems. At our Ankara ETİ Mineral Water pilot Project, we compared process chiller application with the existing R1233zd refrigerant and R134a system. In Istanbul at three food retail market applications, R448A & R452A were used instead of existing R-22 & R404 refrigerants and the old and the new systems were compared.”

Aslantaş also dwelled upon benefits of this entire process for investors and industrialists. “When you examine the cost of having a system, there is a large unseen part of the iceberg. What we want to focus on is this decision-making process that is highly important for industrialists and investors. Because right at that point, every detail of operation cost become apparent. Foremost among them there are important items such as energy consumption, production problem, maintenance costs, and production costs. That is why, a system must be evaluated not just with its initial investment costs but with the totality of all its operation costs. At that stage, it is important to transform data achieved to information and base decisions on this data. For this reason, we included remote monitoring on the systems at pilot projects in the scope of the Demonstration Project. Thanks to this, several values such as temperature measurement, heat value, and pressure value could be measured and compared.”

Uçaner: “Project of introductive and sample applications encouraging refrigerants with low Global Warming Potential (GWP) will be completed until the end of the year”

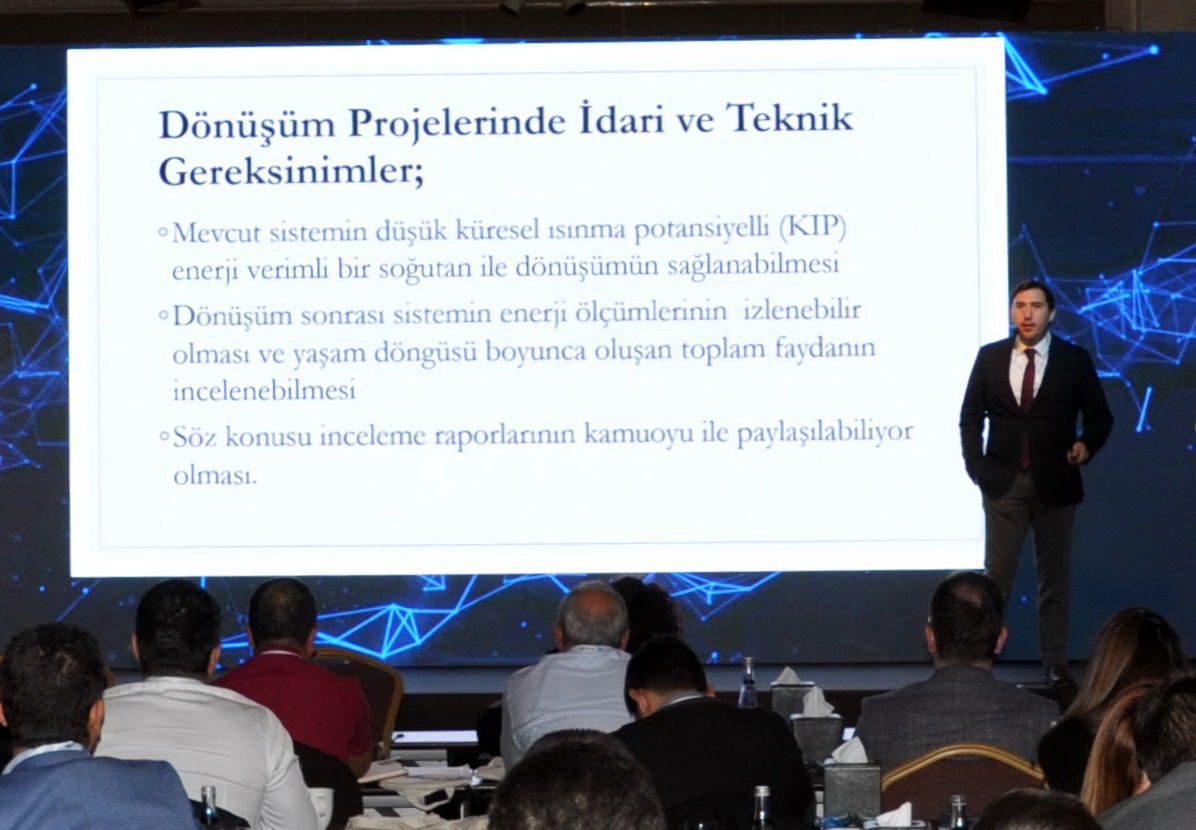

UNIDO National Consultant, Project Counselor Barış Uçaner made his presentation titled “Administrative and Technical Requirements in Transformation Projects.” Uçaner underlined details of technical and administrative details for this project which is one of the factors under UNIDO’s HCFC Phase-Out Management Plan (HPMP). He noted the importance of transforming existing system with an energy-efficient refrigerant with low GWP level and having traceable measurements post-transformation for achieving United Nations Sustainable Development Targets. Uçaner concluded his remarks with: “Project of introductive and sample applications encouraging refrigerants with low Global Warming Potential (GWP) will be completed until the end of the year. With the support of UNIDO we shall continue our efforts to diversify and generalize field of application of our project that has been successfully continuing in the scope of HCFC Phase-Out Management Plan (HPMP).”

Kaymak: “In the scope of the Project, it became possible to use a carbon dioxide compressor with 1/5 lower capacity at a system with the same refrigeration capacity”

Following Uçaner, Erkasis General Manager Erçin Kaymak informed participants about “Examination of NH3/CO2 Cascade Refrigeration Systems.” Kaymak discussed advantages of application of cascade (multistage) refrigeration systems and gave the example of an application. “Our field of expertise is carbon dioxide, ammonia refrigeration systems. 95% of our activities cover establishment of such facilities. Carbon dioxide systems have many advantages compared to ammonia systems. On this issue we had the opportunity to see Algida NH3/CO2 Cascade Refrigeration System application in Izmir. We observed its engineering and construction advantages in place. In general, NH3/CO2 cascade refrigeration systems has high caliber refrigerant carbon dioxide that are sent to rooms in temperatures of -100C and above. Its first advantage is the fact that in case of a leakage, it would not give any damage to food inside since CO2 is already in the air normally. But in case of a leakage at a system with NH3 there are some problems. Another significant advantage is that it is possible to use 1/5 of refrigerator at a place with the same refrigeration capacity. This provides considerable advantages in terms of ease of setup. The facility is readily setup on place. This brings forward effective results in terms of costs and energy savings.”

Tekcan: “With new generation refrigerants daily energy consumption rate of the system decreased from 389 kWh to 195 kWh in 2 months.”

Following Kaymak, Envoytec General Manager Yener Tekcan gave information to participants about “R22/R448A and R404A/R452A Transformation at Sarıyer Grocery Store and Energy Analysis.” Tekcan said: “In our Sarıyer Grocery Store transformation project, sensors were placed on 21 modules in the existing system active for 13 years. Control devices were added to the system and automatization setup was made. The existing thermostatic valves were replaced with electronic valves. Dryer was replaced with the new generation central refrigerant system. More importantly, at refrigerants part R22 refrigerant was replaced with R448A and R404A refrigerant was replaced with R452A. Data achieved after all these efforts was staggering.”

Tekcan noted that the former system was gauged for 2 months and as a result of measurements the average daily energy consumption was found to be 389 kWh. He continued to underline that the total energy consumption in 37 days was 195 kWh with new generation refrigerants. Tekcan expressed that with transformation Project they undertook at Sarıyer Grocery Store, they achieved 49.83% savings on energy consumption. Tekcan emphasized that after achieving such a value, instead of avoiding transformation investments on that area must be increased. He added that the existing high-GWP system that was active for 13 years at Sarıyer Grocery Store which was one of the pilot projects was transformed with a new generation central system to become largely energy efficient and resulted in positive feedback.

Yücel: “We achieved an annual energy saving of around 120,000 Euros”

After Yener Tekcan presentation, Trane Business Development and Sales Manager Ersin Yücel gave his presentation titled “Eti Mineral Water R1233zd Process Chiller Application”. Yücel noted that in the scope of Ingersoll Holding, they aim to decrease negative effects of global warming based on their products by 50% until 2030. He emphasized that they want to achieve this by developing their products, producing more efficient devices, and using innovative gases. He added that the Holding reserved a 500 million USD budget for this purpose. He also noted that until 2020 they will decrease the effect of global warming based on their products by 35%. In this manner Yücel expressed that they have an energy efficient and durable product that has a new generation refrigeration compressor working with R1233zd. According to Yücel, this product which also has a low carbon dioxide emission rate can be used at facilities such as airports, industrial facilities, hotels, and hospitals.

Yücel continued to say: “At Eti Mineral Water Project, 2 devices working with R1233zd that have 5.000 kW refrigeration capacity. The amount of refrigerant in this device is equal to 1043 kg, meaning the amount that 1.043 split air conditioners have. We gave two devices with a total gas level equal to that of 2000 split air conditioners. This system was compared to the traditional system in terms of energy efficiency. According to results of analysis, 1,197 kWh annual savings was reached at energy consumption. This equals annual 120,000 Euros in energy savings. This choice ensured Eti Mineral Water could make 648 tons of savings on CO2 emission annually. Considering a centrifugal compressor operates for about 25 years, savings on energy only achieves a decrease of 16,200 tons in CO2 emission. Thanks to the new generation refrigerants, savings on carbon emission throughout the operating life of the device reaches 1,491 tons which means a total of 17,691 tons of savings on carbon dioxide emission.”

İsa: “We are preparing a LCCP targeted comparative analysis of final reports of three pilot projects under the Demonstration Project that we shall present to you”

Following Yücel’s presentation Technical Team Leader Dr. Kadir İsa informed participants with his presentation titled “Life Cycle Climate Performance (LCCP) Examination of Transformation Projects”. İsa dwelled upon Life Cycle Climate Performance (LCCP) issue which expresses effects of HVACR systems on global warming and said: “In order to make a complete analysis of a system containing refrigerants – it is especially important to take emissions into account as a result of environment-related laws and regulations – we must make an all-encompassing analysis. LCCP Analysis allows for such an evaluation. We are preparing a LCCP targeted comparative analysis of final reports of three pilot projects under the Demonstration Project that we shall present to you.”

İsa drew attention to importance of direct emissions sourcing from refrigerants causing global warming during their operating lives and indirect emissions sourcing from production and energy consumption processes. He also touched upon significant roles carbon dioxide and ammonia play based on their low global warming potentials. İsa noted that when 10 months of operating energy data from Izmir Unilever Algida carbon dioxide/ammonia (CO2/NH3) cascade system was evaluated from LCCP angle, it comes forward as a highly energy efficient system with low operating costs and GWP value.

Following presentations, the Q&A session began and participants exchanged opinions. Project engineer Abdullah Bilgin who had years of sectoral experience was present in the hall and shared his opinion on heat pumps following which Project Coordinator Kıvanç Aslantaş confirmed with UNIDO National Chief Consultant for the Project, Barış Uçaner that following projects must have heat pumps as their work item.

Afterwards the Project team composed of Kıvanç Aslantaş, Barış Uçaner, Kadir İsa, Kemal Öz, Engin Sökmen, Furkan Göl, and Sıla Dinç greeted all participants before lunch.

At the session after lunch participants visited Ankara Eti Mineral Water Facility. They were given detailed information about refrigeration system applied in the scope of the Project.

The final meeting on the Project shall be organized on December 17th, 2019 at Fairmont Quasar Istanbul. Program details shall be announced on unido.sosiad.org.tr website.